Make 2015 3D Printer Test

Make recently published their 2015 3D Printer test results and they also published the test files they used and how to evaluate them. https://makezine.com/2014/11/07/how-to-evaluate-the-2015-make-3dp-test-probes/

I decided to try on my Bukito and I’ve documented what I got here.

The Bukito was also scored on Page 61, so I thought it would be interesting to compare my scores to the magazine scores. I have the PLA cooling fan (with the optional duct( and the magazine model didn’t, so I think that contributed to some of the lower scores in the magazine.

I was using [1.75mm Gray filament]https://seacans.com/collections/pla/products/pla-grey-1-75mm-1kg?variant=845014559) that I purchased from seacans.com

I sliced the models in Cura. This is my settings file.

Here are my settings changes:

- Layer Height 0.2mm

- Printing Speed 30 mm/sec (although for many of these the actual printing speed was much slower due to the small size of the layers).

- I printed the first layer at 210C, and then dropped the temp to 190C for the remaining layers.

- I changed the first layer height to 0.2mm and 100% extrusion width.

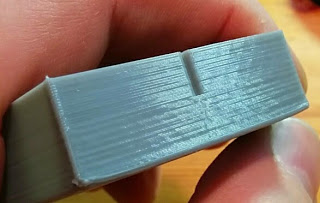

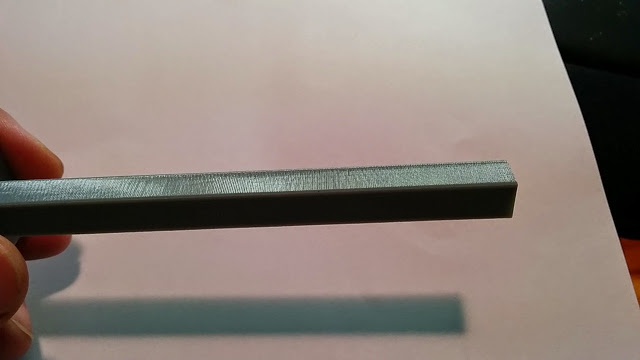

Dimensional Accuracy:

Time: 00:38:08 My Score: 5 - I didn’t count the seam. 4 If I count the seam. Magazine Score: 4

X Measurement: 19.94 mm Y Measurement: 20.05mm There was a seam right on the Y axis - you can see it just left of center in the photo on the left. On the seam I measured 20.18 mm. So I think I’m over extruding just a touch.

I can also see some Z-axis artifacts (my z-axis has 1 mm thread).

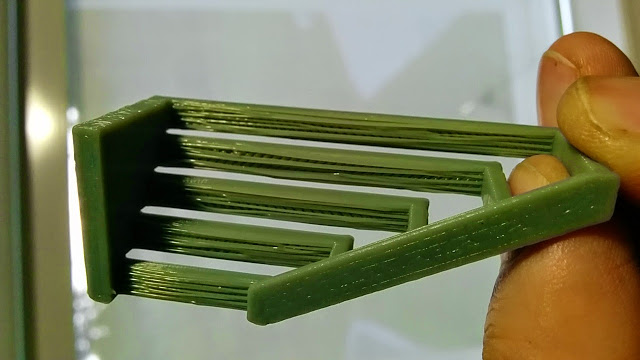

Bridging:

Time: 00:48:21 My Score: Based on the description, I think this is a 4 or 5. The droops were all less than 2mm. Magazine Score: 2

Overhang:

Time: 01:27:00 My Score: 4 Magazine Score: 2

The 70 degree overhand wasn’t pretty on the back, but no drops.

UPDATE: I rotated the model 90 degrees and got much better results. See this post.

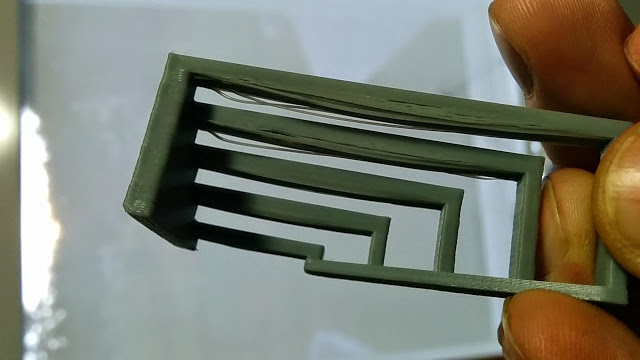

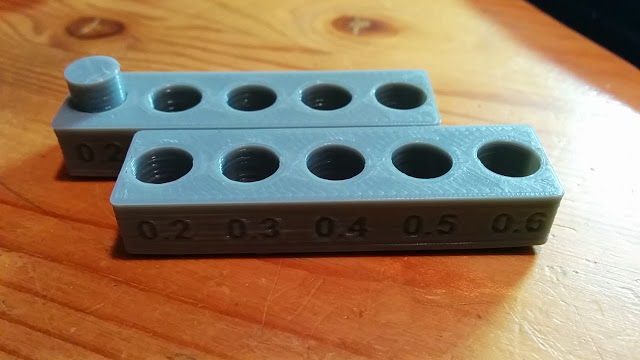

Negative Space Tolerance:

Time: 00:52:41 My Score: 4 Magazine Score: 2

I printed this a couple of times. One time, all of the pegs came out, another time, the smallest clearance peg won’t come out. I can see it moving, but there is something inside holding it in.

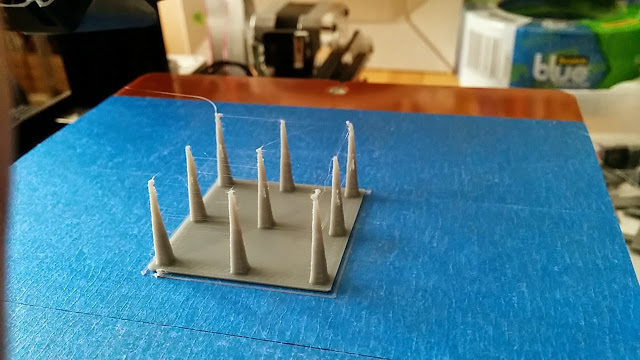

Fine Positive Space Features Performance:

Time: 00:25:05 My Score: 3 Magazine Score: 3

Mechanical Resonance in XY:

Time: 00:38:33 My Score: Pass - no rippling. If I printed at 100 mm/sec then I know I would see some rippling. There was some slight over extrusion on the left-hand corner (seam location). The remaining corners all looked really good. Magazine Score: Pass

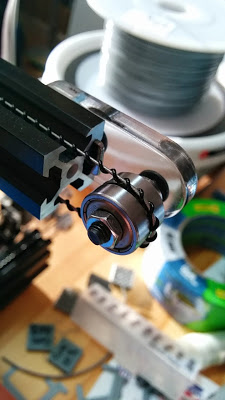

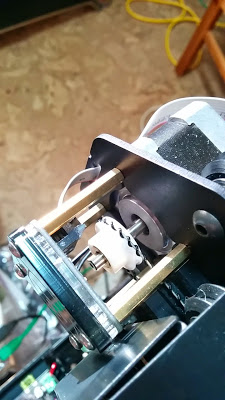

I wound up using the model with 1mm walls. I see a faint herringbone pattern which I think comes from the fact that the synchromesh goes over a pair of bearings at the end rather than over a proper synchromesh pulley (like the one on the stepper motor). I see the same pattern on both X & Y.

[ ]((https://blog.davehylands.com/images/2014-11-12/image-0009.jpg)

[

]((https://blog.davehylands.com/images/2014-11-12/image-0009.jpg)

[ ]((https://blog.davehylands.com/images/2014-11-12/image-0010.jpg)

]((https://blog.davehylands.com/images/2014-11-12/image-0010.jpg)

The photo on the left shows the synchromesh going over the bearing, and the photo on the right shows the synchromesh pulley.

Mechanical Resonance in Z:

Time: 01:29:49 My Score: Pass Magazine Score: Pass

I couldn’t see any of the Z artifacts on this print that I could see on some of the other prints.

I also printed the Maker Faire Robot Action Figure and all of the joints move:

There was a little big of sagging under the arms, but everything else seems to be good.