E3D Bowden Coupler Clip

I started to get some jams on my all metal e3d hotend that came with my MendelMax 3.

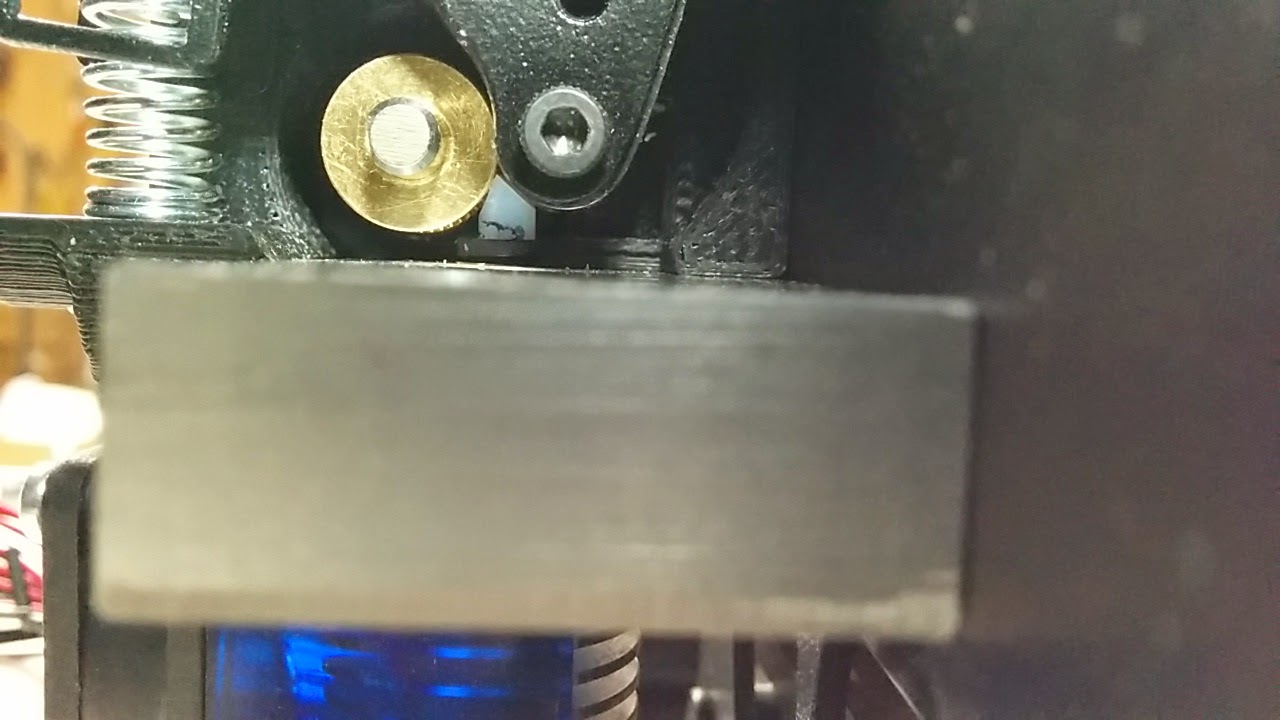

I think I found the culprit. When I cut my PFTE tube, I made it very close to the hob:

and after using it for a while, I noticed tiny little PFTE shavings around the top of the hotend. At the time, it didn’t really occur to me that this might cause a problem.

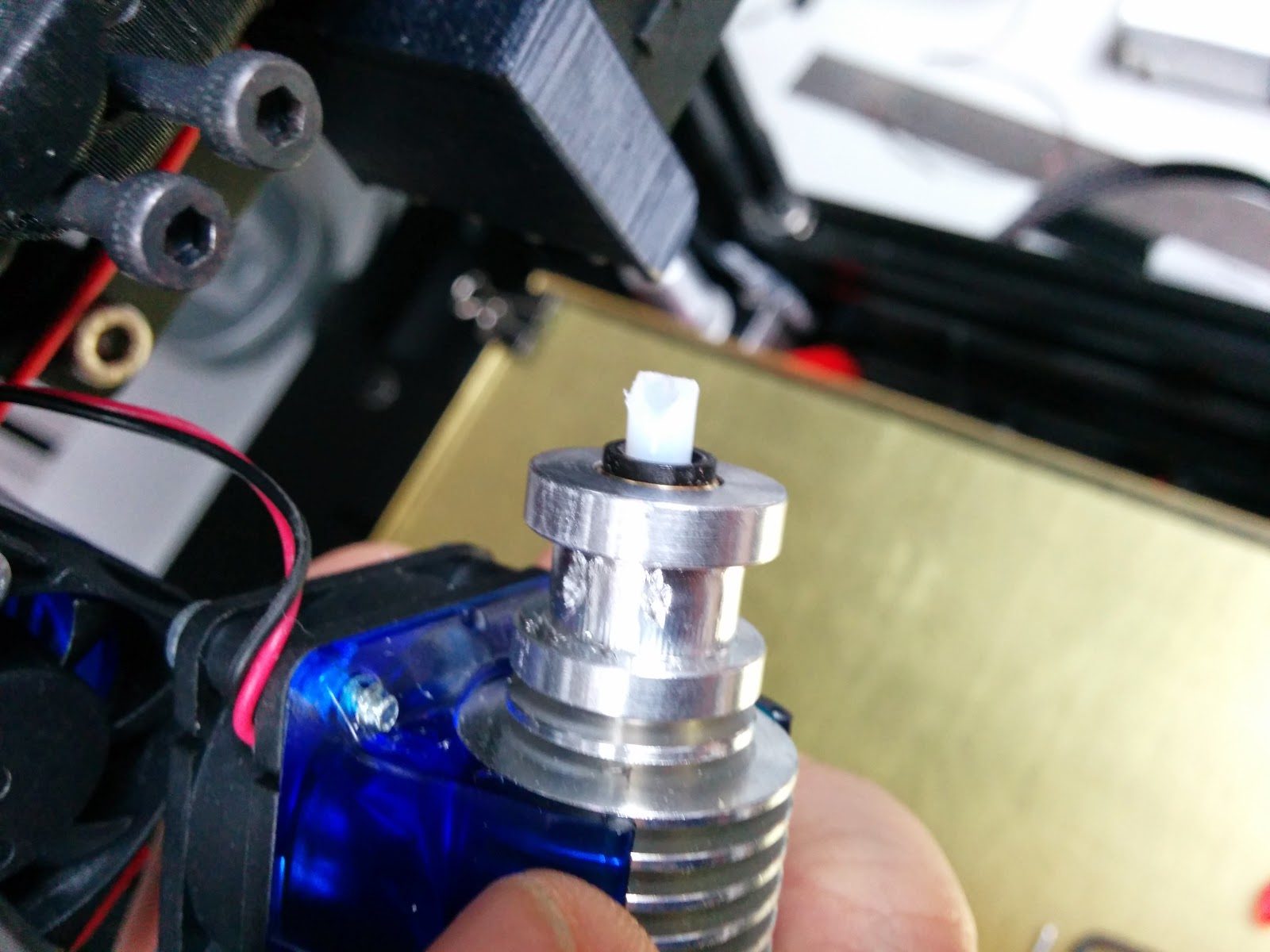

After I started getting the jams, I ripped about the extruder and didn’t find anything obvious wrong. I had done several cold pulls using some cleaning filament. But then I noticed that the PFTE tube could move up and down a bit.

When the black clip at the top of the hotend is positioned like this:

then the tube is secure and won’t move. However, if the black clip gets pushed down, like so:

then the PFTE tube can move up and down by about 1mm. If the top of the tube is less than 1mm fro the hob, then the tube will run into the hob, and the hob can grind off small shavings. If one of those shavings goes down the tube then it can cause a jam. The PFTE has a melting temperature between 260C and 327C (ref), and my hotend typically only runs in the 190C to 240C range.

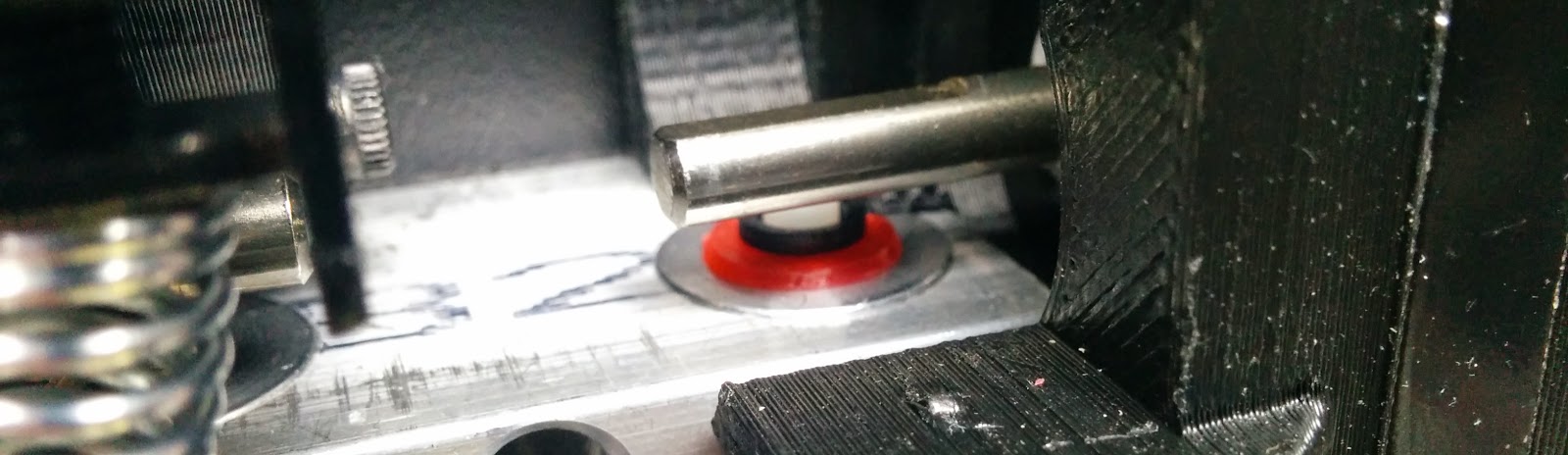

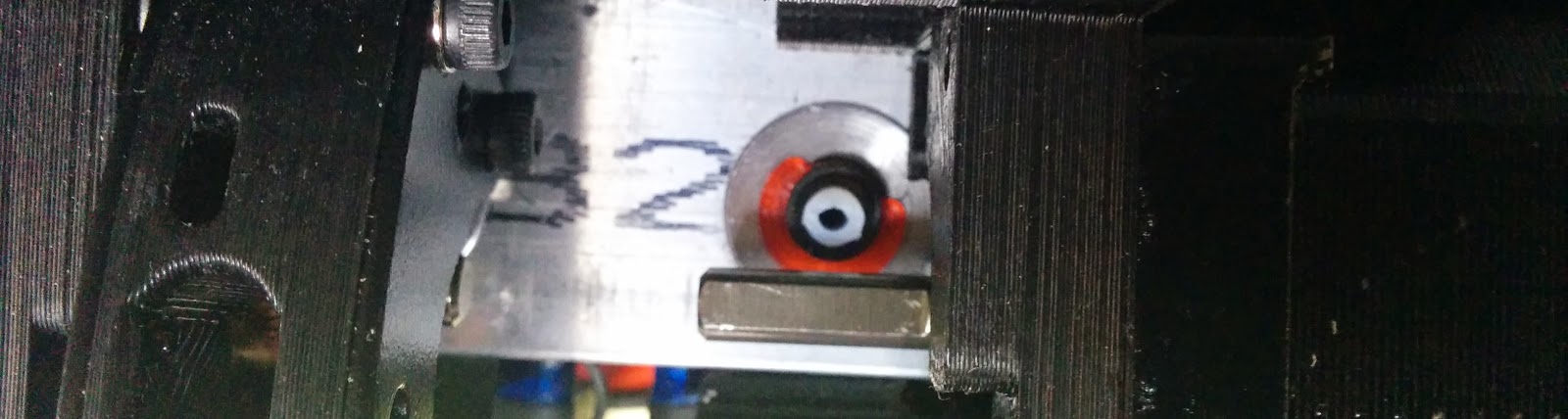

I decided that a small clip which held the black clip in the “out” position was called for. Here’s a photo of the clip:

and a couple photos of it installed:

My STL and CAD files can be found on thingiverse.